Top 10 Shipping Boxes Manufacturer You Should Know About?

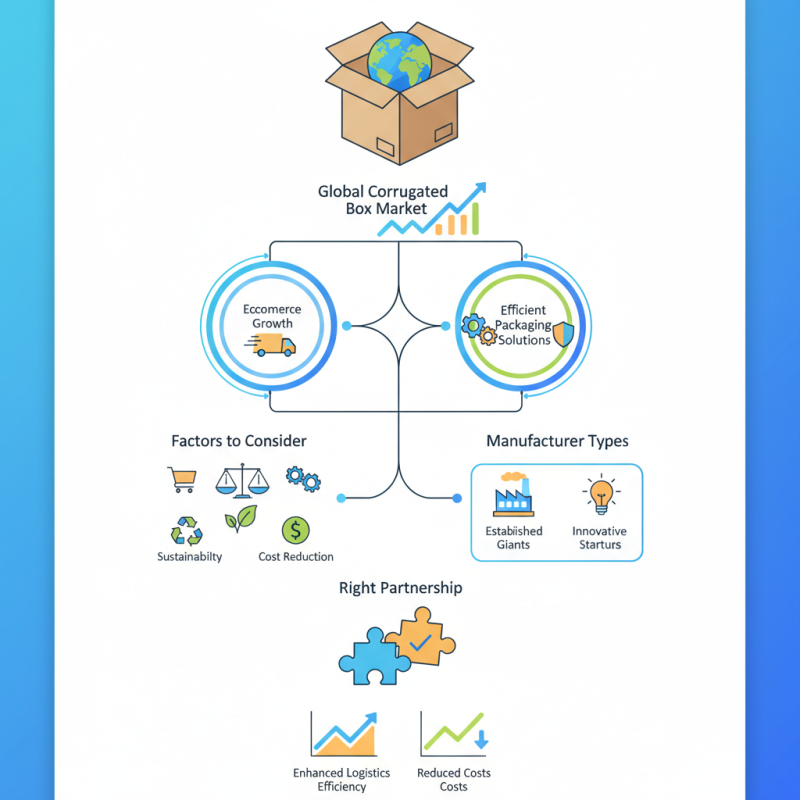

In the dynamic world of logistics, the role of a shipping boxes manufacturer is crucial. Reports indicate that the global corrugated box market was valued at approximately $60 billion in 2021 and is expected to grow steadily. This growth reflects the rising demand for efficient packaging solutions. Ecommerce growth drives the need for reliable shipping boxes that can withstand various transport conditions.

Choosing the right shipping boxes manufacturer can be challenging. There are numerous factors to consider, from material strength to sustainability. Many manufacturers now focus on eco-friendly options, responding to consumer demand for greener practices. However, not all manufacturers meet high standards. Some companies still rely heavily on materials that may not be recyclable.

The landscape of shipping box manufacturing is diverse, with both established giants and innovative startups. This competition can lead to gaps in quality and service. As the industry evolves, understanding key players in this field is essential. The right partnership can enhance your logistics efficiency and reduce costs significantly.

Overview of the Global Shipping Box Manufacturing Industry

The global shipping box manufacturing industry is vast and diverse. It plays a crucial role in logistics. Boxes are not just containers; they are essential for protection and efficiency. Manufacturers are adopting innovative materials. Sustainability is becoming a key focus. Many companies are exploring biodegradable options. This shift reflects growing consumer awareness about environmental impact. Yet, some still rely on traditional materials.

Complexity exists within the manufacturing processes. Speed and cost often drive decisions. In this competitive industry, staying flexible is vital. Challenges like fluctuating raw materials prices can disrupt production. Quality control remains a significant concern. Some manufacturers struggle to maintain high standards under pressure. This constant balancing act defines much of the sector.

Emerging technologies are reshaping the landscape. Automation promises increased efficiency. However, the shift may also lead to job displacement. Training workers for new roles becomes essential. Industry players must adapt to these changes while ensuring product integrity. The landscape continues to evolve, presenting both opportunities and challenges.

Key Factors to Consider When Choosing a Shipping Box Manufacturer

Choosing the right shipping box manufacturer requires careful consideration. Quality is paramount. High-quality materials prevent damages during transit. Look for manufacturers that use durable cardboard or eco-friendly materials. It's essential they can handle your specific product needs.

Another factor is customization. Your boxes should reflect your brand. They must fit your product perfectly. This reduces movement and damage risk. Ask about their design options and production capabilities. An effective manufacturer should offer flexibility in sizes and styles.

Lastly, consider customer service. Responsive support makes a difference. You might face issues with orders or delivery. Clear communication is vital. Reflect on past experiences with support teams before deciding. This can point out strengths and weaknesses in their service. Be prepared to ask questions and address concerns.

Top 10 Renowned Shipping Box Manufacturers and Their Specialties

When choosing a shipping box manufacturer, understanding their specialties can be crucial. Some companies excel in eco-friendly materials. Their boxes are made from sustainable sources. Others focus on custom sizes, ensuring each product fits perfectly. This can minimize shipping costs and enhance protection during transit.

In addition to materials and sizes, consider technology. Some manufacturers use advanced printing techniques. This adds branding elements directly onto boxes. Others prioritize speed, providing quick turnaround times. It's important to keep in mind that not all companies can meet high-volume demands. Check their production capacity before committing. Quality control is another area to watch. Boxes must withstand various shipping conditions, so reliability is key.

While researching manufacturers, identify any gaps in their offerings. Some may not provide adequate customer service. Clear communication is essential. Misunderstandings can lead to mistakes in orders. Finding the right balance of price and quality can feel daunting. However, taking the time to research can yield better results.

Innovative Packaging Solutions Offered by Leading Manufacturers

In the world of shipping, innovative packaging solutions play a crucial role. Leading manufacturers are enhancing how products are transported. These companies focus on sustainability and efficiency. They explore materials that reduce waste and encourage recycling. Biodegradable options are gaining traction. Many manufacturers are also developing reusable boxes to minimize environmental impact.

Custom designs are another trend. Tailored packaging fits products perfectly. This prevents damage during transit. It also creates a better unboxing experience. Some manufacturers offer smart technology integration too. Tracking and monitoring shipments through embedded chips is becoming more common. Such features provide peace of mind to both businesses and consumers.

However, challenges persist. Balancing cost and quality remains a struggle. Often, premium materials come with a higher price tag. Smaller businesses might find it difficult to afford those options. There's a constant push for innovation in design and function. But not all attempts yield success. Companies must learn from their mistakes to improve future solutions.

Sustainability Practices Among Top Shipping Box Manufacturers

Sustainability is becoming essential in the shipping industry. Leading manufacturers are changing how they make boxes. They focus on eco-friendly materials. This includes recycled fibers and biodegradable options. These choices reduce waste and lessen environmental impact.

Some companies excel in sustainable packaging design. They minimize excess material while ensuring safety during transport. However, not every manufacturer has fully embraced these practices. Many struggle to balance cost and sustainability. This gap raises questions about their long-term commitment to the environment.

Efforts to innovate often lead to imperfections. For example, some sustainable boxes may not perform as well as traditional ones. Efficiency in production can also dip when focusing on eco-friendly methods. Manufacturers must continually reflect and adjust their practices. The industry is still evolving, and consistent efforts are necessary for genuine progress.

Top 10 Shipping Boxes Manufacturer You Should Know About - Sustainability Practices

| Manufacturer | Materials Used | Sustainability Initiatives | Certifications | Recycling Programs |

|---|---|---|---|---|

| Manufacturer A | Recycled cardboard, biodegradable materials | Reducing carbon footprint by 30% | ISO 14001, FSC certified | In-house recycling and reuse programs |

| Manufacturer B | Post-consumer recycled materials | Zero waste to landfill initiative | FSC certified, Green Seal | Community recycling partnerships |

| Manufacturer C | Plant-based plastics, recycled fibers | Carbon neutral production | ISO 14001, Cradle to Cradle certified | Full circle recycling program |

| Manufacturer D | Biodegradable corrugated board | Water conservation efforts | FSC certified, LEED certification | Local recycling drives |

| Manufacturer E | Recyclable materials, sustainable inks | Energy-efficient manufacturing | ISO 14001, EcoLabel | Corporate recycling initiative |

Related Posts

-

Top 10 Design Shipping Boxes to Enhance Your Brand Visibility

-

What is the Importance of Custom Design Shipping Boxes for Your Business

-

Revolutionizing Logistics: The Untold Secrets Behind Industrial Shipping Boxes

-

Transform Your Brand with Unique Design Packaging Boxes That Stand Out

-

The Future of Shipping Boxes and Packaging Exploring Sustainable Solutions and Market Trends

-

Why Choose Packaging Corrugated Boxes for Your Shipping Needs