Top 10 Packaging Boxes Manufacturer Tips to Choose the Best for Your Business

When it comes to running a successful business, the importance of effective packaging cannot be overstated. The right packaging not only protects products during transport but also reflects your brand identity and engages customers. Therefore, choosing the right packaging boxes manufacturer becomes a crucial decision that can influence product perception and business performance. With a plethora of options available, it is essential to navigate this selection wisely.

This guide aims to provide you with the top 10 tips for selecting the best packaging boxes manufacturer suited to your needs. From evaluating their material quality and production capabilities to understanding their design flexibility and delivery timelines, these tips will empower you to make informed choices that align with your business goals. Additionally, by considering factors like sustainability and customer support, you can partner with a manufacturer that not only meets your packaging requirements but also contributes positively to your brand's reputation. As you explore these essential criteria, keep in mind that the right manufacturer can make a significant difference in both the efficiency of your operations and the satisfaction of your customers.

Understanding the Importance of Quality Packaging Boxes for Your Business

When it comes to running a successful business, the packaging of your products is often an underestimated component that plays a pivotal role in your overall brand perception and customer satisfaction. Quality packaging boxes not only serve the practical purpose of protecting your products during transit but also offer an opportunity to make a lasting impression on your customers. Well-designed packaging can reflect the values and identity of your brand, creating a sense of trust and reliability among consumers. In an increasingly competitive market, unique and appealing packaging can differentiate your offerings and help you stand out.

Moreover, the importance of investing in high-quality packaging extends beyond aesthetics. Properly designed boxes can enhance the unboxing experience, turning a simple product delivery into a memorable moment for customers. An engaging unboxing experience can lead to increased customer loyalty and encourage repeat purchases. Additionally, efficient packaging can optimize shipping costs and reduce waste, contributing to a more sustainable business model. Ultimately, quality packaging boxes are a reflection of your commitment to your products and customers, making them a crucial aspect of your business strategy.

Top 10 Packaging Boxes Manufacturer Tips to Choose the Best for Your Business

| Tip Number | Tip Description | Importance | Consideration Factors |

|---|---|---|---|

| 1 | Assess Material Quality | High durability and protection of products. | Material type, thickness, and suitability for items. |

| 2 | Customization Options | Brand visibility and customer appeal. | Design flexibility, printing options, and finishes. |

| 3 | Sustainability Practices | Eco-friendly image and compliance with regulations. | Materials used, sourcing, and recycling capabilities. |

| 4 | Shipping Efficiency | Cost savings on logistics and reduced damages. | Box size, weight, and stackability. |

| 5 | Supplier Reputation | Trust and reliability in supply chain. | Review ratings, testimonials, and history of service. |

| 6 | Cost vs Quality Balance | Maximize budget without compromising quality. | Price comparisons and sampling options. |

| 7 | Lead Times and Flexibility | Ensures timely product availability. | Production capabilities and emergency orders. |

| 8 | Regulatory Compliance | Avoid legal issues and product recalls. | Material certifications and safety standards. |

| 9 | Testing and Samples | Real-world performance verification. | Requesting prototypes and conducting trials. |

| 10 | Post-Sales Support | Assistance with any issues after purchase. | Warranty, customer service and responsive support. |

Key Factors to Consider When Choosing a Packaging Boxes Manufacturer

When selecting a packaging boxes manufacturer, several key factors can significantly impact your business's efficiency and product presentation. One crucial aspect to consider is the manufacturer's experience and expertise in the industry. A company with a solid track record is more likely to provide high-quality materials and innovative packaging solutions that cater to your specific needs. Look for a manufacturer that has worked with businesses similar to yours, as this can ensure they understand your requirements and target market.

Another important tip is to assess the range of services offered by potential manufacturers. Some companies might only specialize in standard packaging, while others may provide custom designs, eco-friendly options, or additional services like printing and logistics support. Choosing a manufacturer that can handle all aspects of packaging can streamline your process and save you time and money. Always ask about their design capabilities and whether they offer samples to evaluate the quality of their packaging before making a commitment.

Lastly, consider the manufacturer's commitment to sustainability. With growing awareness of environmental issues, selecting a vendor that prioritizes eco-friendly practices can enhance your brand's reputation. Inquire about their materials and processes to ensure they align with your values. By focusing on these factors, you can find a packaging boxes manufacturer that not only meets your operational needs but also supports your brand's ethos.

Evaluating Manufacturer Capabilities and Production Techniques

When evaluating packaging box manufacturers, it is essential to assess their capabilities and production techniques to ensure they align with your business needs. Begin by examining the scale of their operations. A manufacturer with advanced machinery and a dedicated workforce can typically handle larger orders and maintain consistency in quality. Investigate whether they utilize automated processes, as this can lead to faster production times and decreased human error, ultimately benefiting your supply chain efficiency.

Moreover, understanding the materials used in production is crucial. High-quality packaging not only protects the product but also reflects the brand's values. Look for manufacturers who prioritize sustainability and offer eco-friendly materials, as this is increasingly important to consumers. Additionally, inquire about their quality control measures. A robust quality assurance process ensures that packaging meets industry standards and can withstand the rigors of transportation and storage. By focusing on these aspects, businesses can select a manufacturer that not only meets their requirements but also supports long-term growth and customer satisfaction.

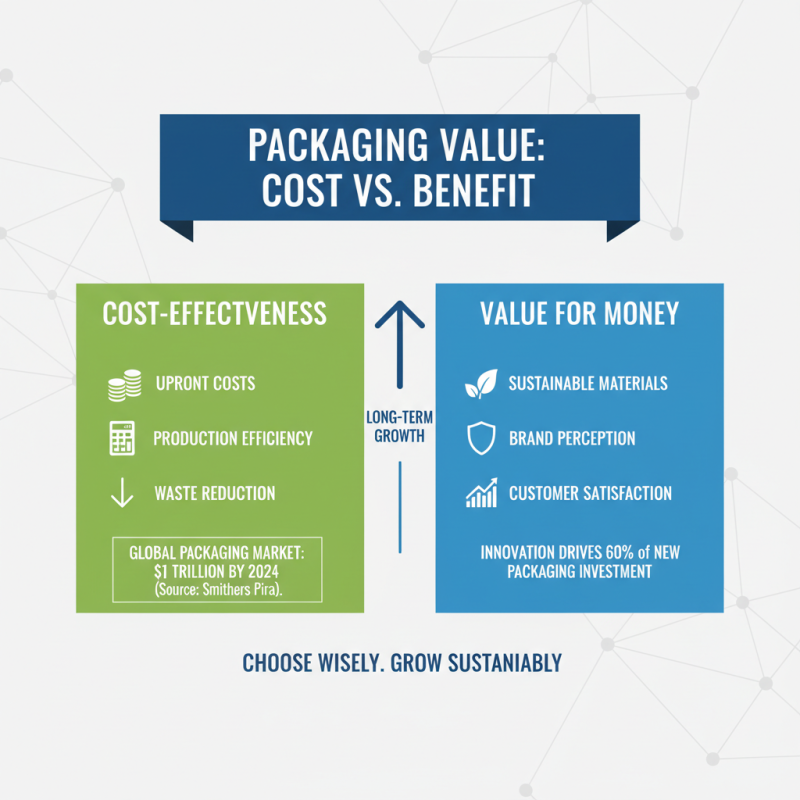

Assessing Cost-Effectiveness and Value for Money in Packaging Options

When evaluating packaging options for your business, assessing cost-effectiveness and value for money is paramount. According to a report by Smithers Pira, the global market for packaging is projected to reach $1 trillion by 2024, with a significant portion dedicated to innovative and sustainable materials. Businesses looking to capitalize on this growth must carefully consider the balance between upfront costs and the long-term benefits of packaging choices.

One critical factor in cost-effectiveness is the material used. Reports indicate that switching to eco-friendly packaging can yield a 30% reduction in shipping costs due to its lightweight nature. Moreover, companies adopting sustainable practices often see a boost in brand loyalty, with 66% of consumers willing to pay more for products from environmentally responsible brands, as highlighted by Nielsen’s research. Failing to factor in these variables can lead to missed opportunities for both cost savings and enhanced customer engagement.

Furthermore, understanding the total cost of ownership (TCO) for packaging options can help businesses identify the best value for money. TCO encompasses the initial purchase price along with costs related to storage, transportation, and disposal. By calculating TCO, companies are better positioned to make informed decisions that align their packaging strategies with overall financial goals, ultimately enhancing their competitive edge in the market.

Sustainability Practices in Packaging: Why They Matter for Your Brand

Sustainability has increasingly become a central pillar in packaging practices, underscoring the importance for brands to adopt eco-friendly strategies. According to a report by Smithers Pira, the market for sustainable packaging is projected to reach $400 billion by 2027, driven by consumer demand for greener alternatives. Brands that incorporate sustainable practices into their packaging not only fulfill regulatory requirements but also align with the growing customer expectation for corporate responsibility. Studies indicate that 72% of consumers are willing to pay more for products with sustainable packaging, which highlights the tangible financial benefits of adopting eco-friendly materials and methods.

Implementing sustainability in packaging involves selecting materials that are recyclable, biodegradable, or made from renewable resources. A survey conducted by McKinsey reveals that companies prioritizing sustainable packaging have seen a 20%-30% increase in brand loyalty. Furthermore, sustainable packaging reduces the overall carbon footprint, with research showing that replacing conventional plastics with biodegradable options can decrease greenhouse gas emissions by up to 50%. By embracing sustainability, brands can enhance their market position, resonate with environmentally conscious consumers, and contribute positively to the planet while simultaneously improving their bottom line.

Sustainability Practices in Packaging: Why They Matter for Your Brand

Related Posts

-

Harnessing Supply Boxes Trends at the 138th Canton Fair in 2025 for Industry Growth

-

The Future of Shipping Boxes and Packaging Exploring Sustainable Solutions and Market Trends

-

Exploring Sustainable Innovations in the Packaging Boxes Industry: A Comprehensive Guide

-

Exploring the Rise of Eco-Friendly Shipping Boxes: What 2023 Data Reveals About Sustainable Practices at Home

-

Unveiling the Future of Packaging Boxes in 2025 Top Digital Trends

-

Maximize Your Logistics Efficiency with Custom Industrial Shipping Boxes