Why Choose Packaging Corrugated Boxes for Your Shipping Needs

When it comes to choosing the ideal packaging solution for shipping needs, packaging corrugated boxes stand out as a leading choice for businesses of all sizes. These boxes are not only lightweight but also provide excellent protection for a wide variety of products, making them essential for ensuring safe transport. Their structure, designed with multiple layers of paperboard, offers superior strength and durability compared to other packaging options, minimizing the risk of damage during transit.

In addition to their protective qualities, packaging corrugated boxes are highly customizable, allowing businesses to tailor sizes and designs to meet their specific requirements. This flexibility is crucial in today’s competitive market, where unique branding and efficient space utilization can significantly impact a company’s logistics and customer satisfaction. Moreover, the eco-friendly nature of corrugated materials aligns with the growing consumer demand for sustainable practices, making these boxes an environmentally responsible choice for shipping.

By opting for packaging corrugated boxes, businesses can not only enhance the safety and presentation of their products but also contribute to environmental sustainability. It’s clear that selecting the right packaging is not just a functional decision but a strategic one, as it can influence everything from cost-effectiveness to brand perception. Thus, understanding the benefits of corrugated boxes is vital for any company looking to optimize their shipping processes.

Advantages of Using Corrugated Boxes for Shipping

When it comes to shipping products efficiently and securely, corrugated boxes stand out as a top choice for businesses. One of the main advantages of using corrugated boxes is their exceptional strength and durability. Made from multiple layers of paper, these boxes provide excellent protection against rough handling during transit. This robust construction absorbs shocks and impacts, ensuring that even fragile items arrive safely at their destination. Furthermore, the lightweight nature of corrugated boxes helps to reduce shipping costs, making them an economical option for businesses looking to optimize their expenditure.

In addition to their protective qualities, corrugated boxes are also incredibly versatile. They come in various sizes and can be custom-designed to fit an array of products, which is essential for efficient packing and shipping. This customization not only minimizes wasted space but also enhances the unboxing experience for the customer. Moreover, corrugated boxes are environmentally friendly, as they are made from recyclable materials, appealing to businesses that prioritize sustainability. By choosing corrugated boxes for shipping, companies can ensure their products are delivered in good condition while also supporting eco-friendly practices.

Advantages of Using Corrugated Boxes for Shipping

Types of Corrugated Boxes and Their Uses

When it comes to packaging, corrugated boxes are a popular choice due to their versatility and strength. There are several types of corrugated boxes, each serving different purposes in shipping and storage. Regular slotted containers (RSC) are among the most common types, ideal for shipping a variety of products due to their efficient design and ease of assembly. They can be customized in size and printed for branding, making them suitable for both retail and e-commerce businesses.

Another type is the half slotted container (HSC), which features an open top and is perfect for items that require ease of access. These boxes are frequently used for packing heavy or bulk items, providing reliable support during transport. Furthermore, specialized corrugated boxes like die-cut boxes offer unique shapes tailored to specific products, offering enhanced protection and preventing damage. In addition, double-wall corrugated boxes are designed for heavier loads and provide extra durability, making them ideal for shipping fragile items. Each type of corrugated box plays a vital role in ensuring goods are shipped safely and efficiently.

Why Choose Packaging Corrugated Boxes for Your Shipping Needs - Types of Corrugated Boxes and Their Uses

| Type of Corrugated Box | Description | Common Uses | Strength |

|---|---|---|---|

| Regular Slotted Container (RSC) | Standard box with flaps that meet in the center. | General shipping, retail packaging | Medium to high strength |

| Die-Cut Box | Custom-shaped box tailored for specific products. | Unique items, gifts, retail products | Varies based on design |

| Double-Wall Box | Two layers of fluted material for added durability. | Heavy items, electronics, glassware | Very high strength |

| Bulk Box | Larger box designed to hold bulk quantities of products. | Warehouse storage, bulk shipping | High strength |

| Mailing Box | Designed specifically for mailing with a secure closure. | E-commerce, shipping small items | Medium strength |

Environmental Benefits of Corrugated Packaging

Corrugated packaging has gained immense popularity in recent years, primarily due to its environmental advantages. According to the American Forest & Paper Association, corrugated boxes are made from more than 80% recycled paper, making them a sustainable packaging choice. The production process of these boxes consumes less energy compared to other packaging materials, significantly lowering carbon emissions. It's estimated that using corrugated packaging can reduce greenhouse gas emissions by 25% compared to other forms of cardboard packaging, contributing to a more eco-friendly supply chain.

When it comes to recycling, corrugated boxes have an impressive recovery rate. The Fiber Box Association states that around 96% of corrugated boxes are recycled, dramatically reducing landfill waste and conserving natural resources. Moreover, the biodegradable nature of corrugated materials means that they can decompose efficiently, returning valuable nutrients to the soil. Businesses opting for corrugated packaging not only stand to benefit from compliance with increasing eco-regulations but also resonate with environmentally conscious consumers, enhancing brand loyalty.

**Tips:** Opt for lightweight corrugated materials to save on shipping costs, as this can lead to reduced fuel consumption during transportation. Additionally, consider incorporating eco-friendly ink and adhesives in your packaging design to further minimize environmental impact. Remember to communicate your sustainable practices to customers, as transparency can strengthen their trust and support for your brand.

Cost-Effectiveness of Corrugated Boxes in Shipping

When it comes to shipping needs, corrugated boxes stand out due to their cost-effectiveness. According to the Freedonia Group, the demand for corrugated boxes is projected to exceed $35 billion by 2025, indicating their significant role in the shipping industry. The lightweight yet durable nature of these boxes reduces transportation costs, allowing businesses to save on freight expenses. Furthermore, their design ensures the protection of products, minimizing the risk of damage during transit, which can lead to costly replacements and lost revenue.

Tips: When selecting corrugated boxes, look for options with recycled content to further reduce costs and enhance sustainability. Always consider the size and thickness of the boxes based on the weight and fragility of the items being shipped to ensure maximum protection and cost savings.

Additionally, a report from Smithers Pira highlights that corrugated boxes are increasingly being favored due to their versatility and ease of customization. Businesses can design boxes that cater to their specific items, ensuring that packaging truly reflects their product's dynamics. This customized approach can lead to reduced packaging waste and better space utilization during shipping, ultimately driving down shipping costs.

Best Practices for Packing and Shipping with Corrugated Boxes

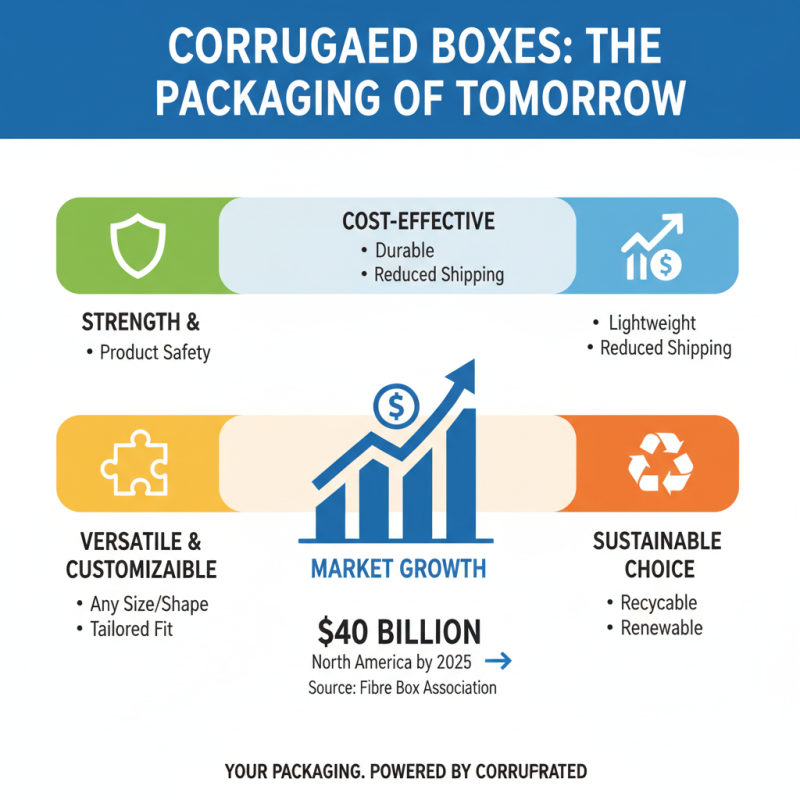

When it comes to packing and shipping, corrugated boxes stand out as a top choice due to their strength and versatility. According to a report from the Fibre Box Association, the use of corrugated packaging has been growing consistently, with an estimated market size reaching $40 billion in North America alone by 2025. This material not only offers excellent protection for products during transit but is also lightweight, which helps to reduce shipping costs. Moreover, corrugated boxes are easily customizable, allowing businesses to tailor their packaging to fit various shapes and sizes, ensuring that products are secure throughout the shipping process.

Best practices for packing with corrugated boxes include ensuring proper cushioning to prevent items from shifting within the box. Using biodegradable packing materials, such as paper or air-filled cushions, can further enhance protection. It's also crucial to select the right box size: too large a box can lead to excess movement, while too small a box can compromise the integrity of the packed items. The International Corrugated Case Association recommends testing pack performance using the Edge Crush Test (ECT) to determine the box's strength, thus ensuring that the packaging meets the necessary durability standards for transportation. By adhering to these practices, businesses can optimize their shipping processes while providing reliable protection for their products.

Related Posts

-

How to Choose the Right Packaging Supplies Boxes for Your Business Needs Based on Industry Trends

-

What is the Importance of Choosing the Right Shipping Boxes for Your Home

-

Emerging Trends in Packaging Supplies Boxes at the 2025 China Import and Export Fair by Industry Analysis

-

What is the Importance of Custom Design Shipping Boxes for Your Business

-

Transform Your Brand with Unique Design Packaging Boxes That Stand Out

-

Top 10 Design Shipping Boxes to Enhance Your Brand Visibility