What is the Importance of Supply Boxes in Modern Logistics?

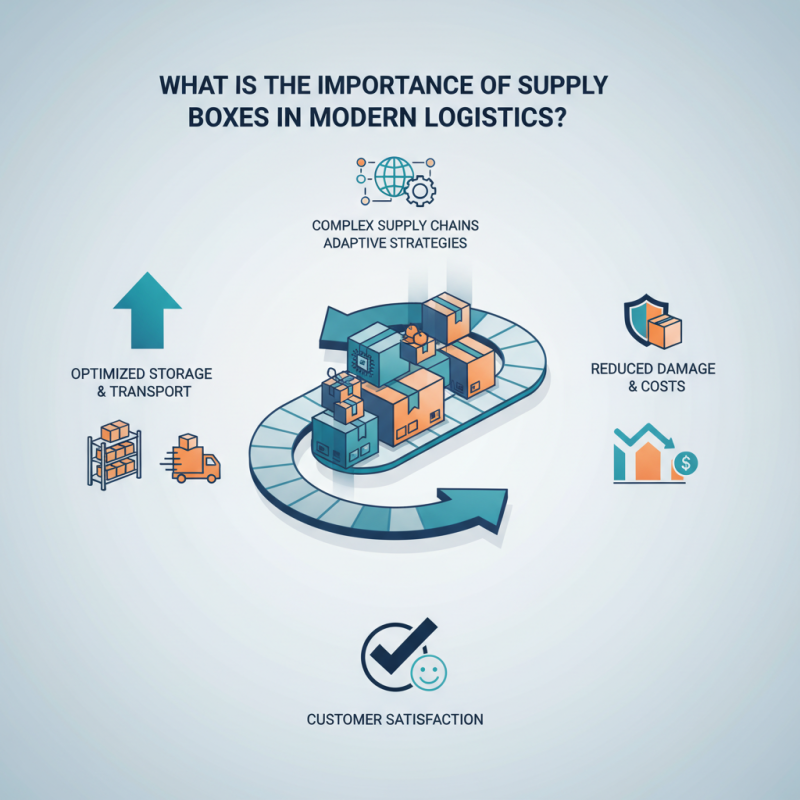

In today's fast-paced logistics industry, the role of supply boxes is crucial. John Smith, a renowned logistics expert, emphasizes this by saying, "Supply boxes are the backbone of efficient delivery systems." These boxes optimize the storage and transport of goods, ensuring items reach their destinations safely and on time.

Supply boxes come in various sizes and designs, catering to diverse needs. They can hold anything from electronics to perishables. However, not all supply boxes are created equal. Some may be too flimsy or ill-suited for their contents. Companies often overlook these details, often leading to damaged goods and increasing costs. That's a critical oversight in modern logistics.

Moreover, the complexity of supply chains can make it challenging to implement the best practices for using supply boxes. Businesses regularly need to adapt their strategies to suit changing demands. Many find that investing in high-quality supply boxes pays off in the long run. Reflecting on this, it is essential for companies to recognize the impact of their supply boxes on overall efficiency and customer satisfaction.

Role of Supply Boxes in Streamlining Logistics Operations

Supply boxes play a critical role in modern logistics. They enhance the efficiency of supply chain operations. These boxes facilitate organization and protect goods during transport. Their standardized sizes allow for easier stacking and storage. This efficiency ultimately reduces costs and time.

Incorporating supply boxes into logistics can streamline operations significantly. For instance, they reduce the risk of damage. A well-organized delivery system can help track inventory better. Clear labeling on boxes aids in quick identification. This helps prevent mix-ups and delays. It's vital, however, to ensure boxes are not overstuffed. Overloading can lead to structural failures.

Tips: Always measure and label your supply boxes. Regularly inspect them for wear and tear. Consider using different colors for various items. This will enhance visual management. Keep communication open within your logistics team. Discuss what works and what doesn’t. Learning from mistakes is essential for improvement.

What is the Importance of Supply Boxes in Modern Logistics? - Role of Supply Boxes in Streamlining Logistics Operations

| Dimension | Description | Impact |

|---|---|---|

| Cost Efficiency | Reduction in overall shipping costs through optimized packing. | Saves up to 20% in logistics expenditure. |

| Time Management | Faster loading and unloading due to standardized box sizes. | Reduces handling time by 15%. |

| Inventory Control | Easier tracking of stock and supply levels. | Improves inventory accuracy by 30%. |

| Sustainability | Use of recyclable materials in supply boxes. | Contributes to a 25% reduction in carbon footprint. |

| Product Protection | Enhanced protection for goods during transit. | Decreases damage rates to under 2%. |

Impact of Supply Boxes on Inventory Management Efficiency

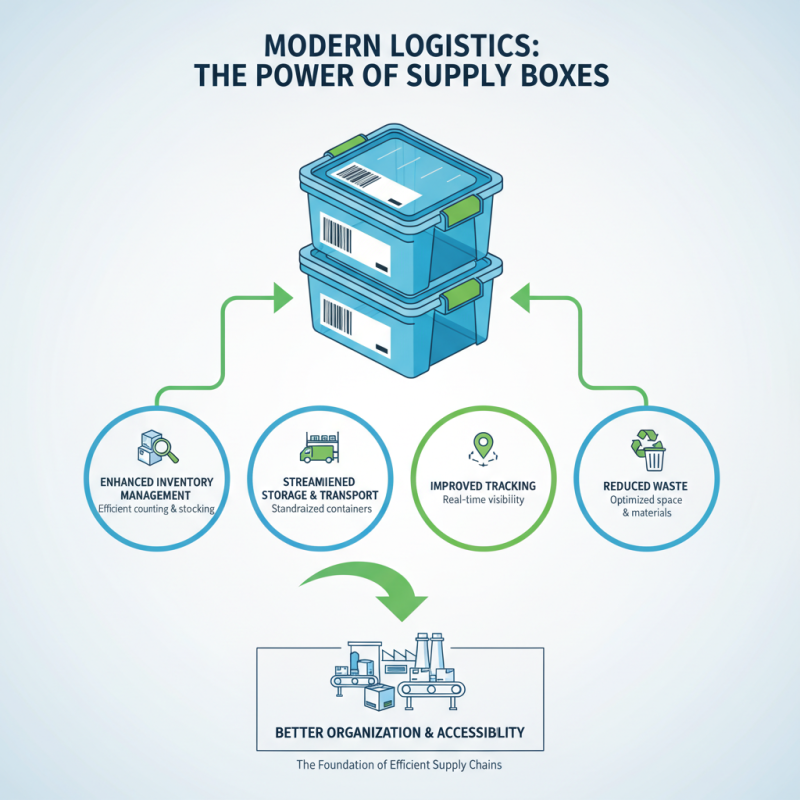

Supply boxes play a crucial role in modern logistics. They enhance inventory management efficiency. By using standardized containers, companies can streamline the storage and transportation of goods. This ensures better organization and accessibility within warehouses. Reducing waste and improving tracking beneath each box is essential.

Inventory turnover rates improve significantly when supply boxes are used. Products can be easily identified and accessed. For example, color-coded boxes facilitate quick sorting and retrieval. However, improper labeling can lead to confusion. Employees might waste time searching for items. Regular audits and staff training are necessary to mitigate this issue.

Incorporating technology with supply boxes can further enhance efficiency. RFID tags can track movement and inventory levels in real-time. However, the implementation process can be challenging. Employees may resist adopting new systems. This resistance can cause delays. Addressing these obstacles is key to utilizing supply boxes effectively. Overall, the benefits of supply boxes in inventory management are evident yet complex.

Benefits of Standardized Packaging in Supply Chain Processes

Standardized packaging plays a crucial role in modern logistics. It enhances efficiency and reduces costs.

According to a report by the Council of Supply Chain Management Professionals, standardized packaging can decrease shipping errors by 25%. These errors often lead to delays and customer dissatisfaction.

Moreover, using uniform supply boxes streamlines handling processes. It allows for easier stacking and storage in warehouses. This leads to better space utilization. Statistics show that companies adopting standardized packaging can increase warehouse capacity by up to 30%. However, some organizations still struggle with integration. They may hesitate to shift from traditional methods.

Quality control also benefits from standardized packaging. It consistently protects products during transit. A study revealed that losses due to damaged goods could be reduced by 15% with proper packaging practices. Yet, not every industry has embraced this. Many continue to rely on outdated systems. This hesitation can hinder overall progress in supply chain efficiency.

Technological Advancements in Supply Box Design and Functionality

In modern logistics, supply boxes play a vital role in ensuring efficiency. Recent technological advancements have transformed their design and functionality. These boxes now incorporate smart features, enhancing tracking and inventory management. RFID tags and sensors can provide real-time updates, making it easier for businesses to monitor their shipments.

However, with innovation comes challenges. Not all supply boxes are equally robust. Some designs may fail under extreme conditions, leading to product loss. Companies are constantly exploring materials and structures, but not every attempt succeeds. There is a need for continuous improvement in durability and adaptability.

Moreover, the ecological impact of supply box production cannot be overlooked. Many materials are not biodegradable, which poses environmental risks. As logistics aims for sustainability, finding eco-friendly alternatives is crucial. Balancing efficiency with environmental responsibility remains a work in progress in the industry.

Importance of Supply Boxes in Modern Logistics

This chart illustrates the various dimensions of importance associated with supply boxes in modern logistics. The impact levels indicate how critical each dimension is in contributing to the overall efficiency and effectiveness of the logistics process.

Challenges and Solutions in Implementing Supply Boxes in Logistics

In modern logistics, supply boxes play a critical role. They streamline the movement of goods from suppliers to consumers. However, implementing supply boxes presents several challenges. One major issue is the standardization of box sizes. Different industries often use various dimensions. This inconsistency can lead to inefficiencies in storage and transport.

Another challenge is the tracking of supply boxes. Without reliable tracking systems, lost items increase significantly. This can complicate inventory management and delays in delivery. Companies need to invest in better tracking technology. Additionally, training staff on new systems can be time-consuming. Resistance to change among employees can also hinder the adoption of supply boxes.

Moreover, environmental concerns are becoming more pressing. Many supply boxes are not reusable or recyclable. This creates unnecessary waste in the supply chain. Some companies underestimate the impact this has on sustainability. It’s essential to consider eco-friendly alternatives. As logistics continues to evolve, addressing these challenges will be vital for success.

Related Posts

-

How to Choose the Right Packaging Supplies Boxes for Your Business Needs Based on Industry Trends

-

How to Choose the Best Supply Boxes for Your Needs: A Complete Guide

-

What is the Importance of Choosing the Right Shipping Boxes for Your Home

-

Emerging Trends in Packaging Supplies Boxes at the 2025 China Import and Export Fair by Industry Analysis

-

Unlocking Market Opportunities for Supply Boxes at the 138th Canton Fair 2025 in China

-

What is the Importance of Custom Design Shipping Boxes for Your Business