How to Choose the Best Supply Boxes for Your Needs: A Complete Guide

Selecting the right supply boxes is a crucial decision for businesses across various industries, whether for storage, shipping, or inventory management. According to a recent report by the Packaging Industry Association, the global market for supply boxes is projected to exceed $10 billion by 2025, highlighting the significant demand and evolution in this sector. As firms strive for efficiency and organization, understanding the specific requirements to optimize the utilization of supply boxes can lead to substantial cost savings and improved operational workflow.

Industry expert John Miller, a leading consultant with over 20 years in logistics and packaging solutions, emphasizes the importance of a tailored approach. He states, "Choosing the right supply boxes is not just about space; it’s about enhancing productivity and reducing waste." His insights reflect a growing recognition of strategic packaging, which underscores that the selection process must account for various factors including size, material, and purpose. As businesses continue to navigate complex supply chain challenges, this complete guide will illuminate the critical considerations and best practices for selecting supply boxes that align with unique operational needs.

Understanding Different Types of Supply Boxes Available on the Market

When it comes to choosing the best supply boxes for various applications, understanding the different types available on the market is crucial. Supply boxes come in several materials, shapes, and sizes, each tailored to meet specific needs. According to a recent report by Research and Markets, the global industrial storage box market is expected to reach $12 billion by 2025, reflecting the growing demand for efficient storage solutions across various sectors.

Plastic supply boxes are highly popular due to their lightweight, durability, and resistance to chemicals. The versatility of these boxes makes them suitable for both industrial and household uses. On the other hand, metal supply boxes are favored in environments where strength and protection from external damage are paramount. A study from IBISWorld indicates that the metal storage container market has seen a steady annual growth rate of 3.5% over the last five years, driven primarily by the manufacturing sector's need for robust storage solutions. Understanding these distinctions will not only help you choose supply boxes that fit your needs but will also enable you to make informed decisions based on industry trends and demands.

Assessing Your Specific Needs for Storage Solutions

When selecting the best supply boxes for your needs, it is crucial to first assess your specific storage requirements. This involves understanding the types of items you plan to store, their sizes, and the environment in which they will be stored. For instance, if you need to store agricultural produce, you may require eco-friendly packaging solutions that not only protect the items but also contribute to sustainability efforts. This aligns with the growing emphasis on renewable resources and eco-friendly practices highlighted in recent discussions about agricultural technology.

Additionally, consider the scalability of your storage solutions. Just as businesses are adopting scalable infrastructure to accommodate increased computational demands in various sectors, your choice of supply boxes should also allow room for growth. Whether it’s expanding storage capacity for seasonal inventory or transitioning to more energy-efficient storage methods, the ability to adapt will ensure your storage solution remains effective in the long term.

Evaluating these factors not only enhances operational efficiency but also aligns your choices with broader economic and environmental priorities, such as the drive towards clean energy initiatives.

Evaluating Material Durability and Weight Capacity of Supply Boxes

When selecting supply boxes, evaluating material durability is paramount. Different materials offer varying levels of strength and resilience. For instance, plastic supply boxes are lightweight and resistant to moisture but may not withstand heavy impacts. Conversely, metal boxes tend to provide superior durability and can handle heavier loads, making them ideal for long-term storage and transportation of heavier supplies. It’s essential to consider the environment in which the box will be used, as certain materials perform better in specific conditions; for example, stainless steel is preferable in humid or corrosive environments.

Weight capacity is another critical factor in choosing the right supply box. Assessing how much weight the box can safely carry ensures that it won’t buckle or break under pressure, which can not only damage your supplies but also present safety risks. Manufacturers usually provide specifications for weight limits based on materials and construction quality. It’s wise to choose boxes with a capacity that exceeds your expected load to allow for additional items without reaching maximum limits. By carefully considering both material durability and weight capacity, you can select supply boxes that meet your specific needs effectively.

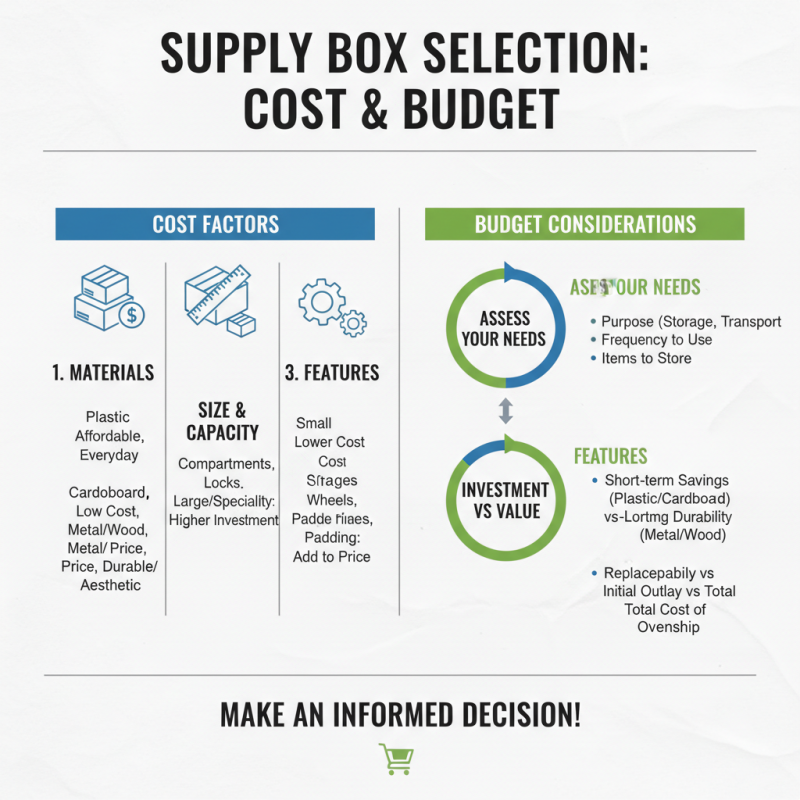

Comparing Costs and Budget Considerations for Supply Boxes

When selecting supply boxes, understanding the costs and budget considerations is essential for making an informed decision. The price of supply boxes can vary significantly based on materials, size, and features. For instance, plastic boxes tend to be more affordable, making them a popular choice for everyday needs, while metal or high-quality wood options may carry a higher price tag due to durability and aesthetics. It's crucial to assess how much you are willing to invest in a supply box that aligns with your requirements.

Budgeting for supply boxes should also take into account not just the initial purchase price, but potential ongoing expenses. Consider whether the boxes will need to be replaced frequently, if they will require maintenance, or if additional accessories are necessary for your specific use. Additionally, comparing prices from different suppliers can help identify the best deals and value for your investment. By carefully evaluating your needs and analyzing costs, you can ensure that you choose supply boxes that fit both your functional requirements and budget constraints efficiently.

Tips for Organizing and Maximizing Space with Your Supply Boxes

When it comes to organizing your supplies, the right supply boxes can make all the difference. Choosing boxes that suit your specific needs is essential, and strategically arranging these boxes can maximize your space. Begin by assessing the type and volume of supplies you have; this will guide you in selecting boxes that fit perfectly in your available storage area. Opt for modular boxes that can stack easily, allowing you to utilize vertical space effectively. Labels can also enhance organization, ensuring you can quickly find what you need without rummaging through multiple containers.

To further optimize your storage, consider box sizes carefully. Smaller boxes can be used for tools or miscellaneous items, while larger boxes can hold bulkier supplies. Utilize drawer dividers or internal compartments within boxes to keep similar items together, which not only saves time but also minimizes clutter. Additionally, placing frequently used items at eye level can improve accessibility, making your workspace or storage area more efficient. By incorporating these tips, you can transform your supply storage into a neat and functional system that enhances productivity.

Related Posts

-

How to Choose the Right Packaging Supplies Boxes for Your Business Needs Based on Industry Trends

-

What is the Importance of Choosing the Right Shipping Boxes for Your Home

-

Emerging Trends in Packaging Supplies Boxes at the 2025 China Import and Export Fair by Industry Analysis

-

Unlocking Market Opportunities for Supply Boxes at the 138th Canton Fair 2025 in China

-

What is the Importance of Custom Design Shipping Boxes for Your Business

-

Maximize Your Logistics Efficiency with Custom Industrial Shipping Boxes