How to Choose the Best Shipping Packaging Boxes for Your Business Needs

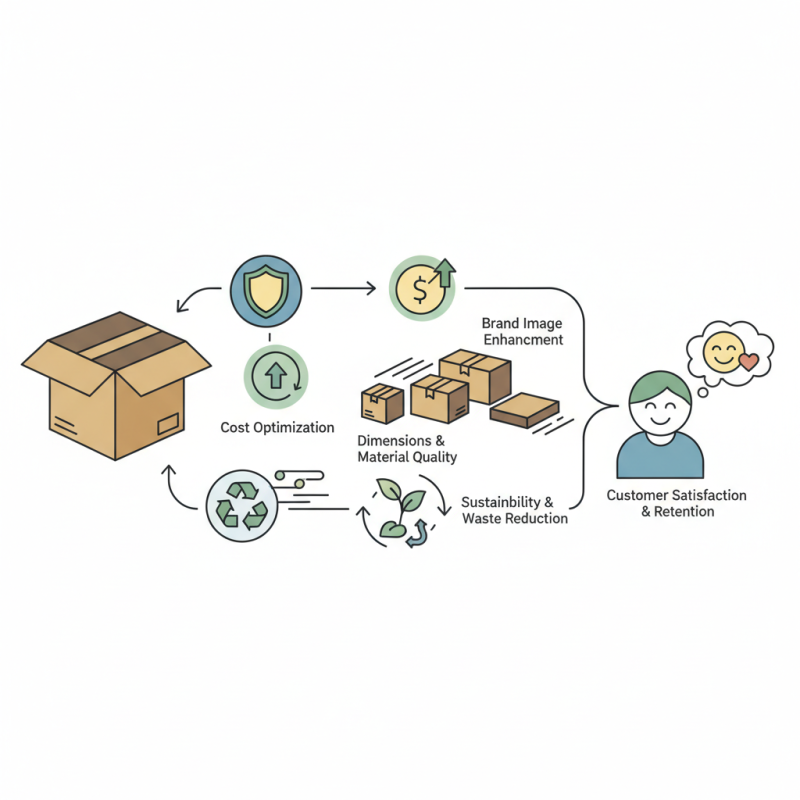

Choosing the right shipping packaging boxes is a critical decision for any business that wants to ensure the safety of its products while optimizing costs. According to industry expert Jane Thompson, “The right packaging not only protects your products but also enhances your brand image.” In today’s competitive market, understanding the nuances of shipping packaging boxes can significantly impact customer satisfaction and retention.

As e-commerce continues to surge, companies are faced with an overwhelming array of choices when it comes to packaging solutions. Factors such as material quality, box dimensions, and design can influence not only the cost-effectiveness of shipping but also the first impression consumers have when they receive their orders. A thoughtful approach to selecting shipping packaging boxes can help businesses reduce waste, cut expenses, and ultimately foster meaningful connections with customers through a well-presented delivery.

In this guide, we will explore essential considerations and best practices for selecting shipping packaging boxes that align with your business needs, ensuring that every product arrives in perfect condition while reinforcing your brand's commitment to quality and sustainability.

Understand Your Business Requirements for Packaging

When selecting the best shipping packaging boxes, understanding your business requirements is crucial. Your packaging needs will vary based on the type of products you sell, the shipping methods you use, and your target customer base. For instance, fragile items necessitate sturdy boxes with cushioning materials to prevent damage during transit, while lightweight products might require more economical options. A thorough assessment of your business model can help identify the packaging that aligns with your objectives.

**Tips:** Evaluate the dimensions and weight of your products carefully. Opt for boxes that fit your items snugly to minimize movement during shipping, which can reduce the risk of damage. Additionally, consider the environmental impact of your packaging choices. Using sustainable materials can enhance your brand image and attract eco-conscious customers.

Another essential aspect to consider is your branding. Custom packaging not only serves a functional purpose but also presents an opportunity to reinforce your brand identity. From colors and logos to unique designs, packaging can communicate your brand values and create a memorable unboxing experience.

**Tips:** Invest in quality printed materials for your packaging that reflect your brand's ethos. Consistency in design across all touchpoints enhances customer recognition and loyalty.

Identify Different Types of Shipping Packaging Boxes

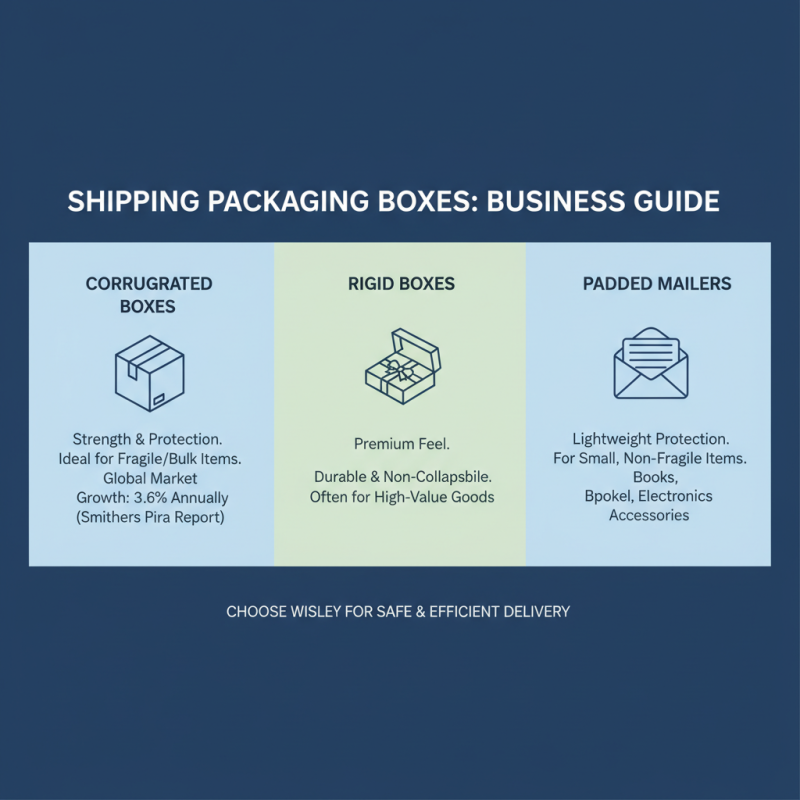

When selecting the best shipping packaging boxes for your business needs, it’s essential to identify the different types available to ensure that your products reach customers safely and efficiently. The most common types of shipping boxes include corrugated boxes, rigid boxes, and padded mailers. According to a report from Smithers Pira, the global corrugated packaging market is projected to grow at a rate of 3.6% annually, indicating its popularity for various business applications. Corrugated boxes offer excellent strength and protection, which makes them ideal for shipping fragile items or bulk supplies.

Rigid boxes, on the other hand, provide a premium unboxing experience due to their sturdy construction. They are often used for high-end products such as electronics or luxury goods. The market for rigid boxes is also expanding, with a forecasted growth of 4.1% per year, as reported by Technavio. Padded mailers, typically made of bubble wrap or similar materials, are favored for lightweight items that require some protection but do not need the rigid structure of traditional boxes. The use of padded mailers has increased by approximately 15% in recent years, driven by the rise in e-commerce where safe and efficient shipping options are crucial. By understanding these different types of packaging boxes, businesses can make informed decisions to enhance their shipping processes and overall customer satisfaction.

Assess the Durability and Protection Levels of Packaging

When selecting shipping packaging boxes, evaluating the durability and protection levels is essential to ensure that products arrive safely at their destination. Start by considering the type of materials used in the construction of the boxes. Corrugated cardboard is a popular option due to its strength and lightweight properties, making it an ideal choice for a variety of products. It's crucial to assess the weight of the products being shipped, as heavier items require sturdier packaging to prevent damage during transit.

Tips: When choosing your packaging, opt for double-wall boxes for extra protection if you’re shipping fragile items. Additionally, consider using foam inserts or bubble wrap to provide cushioning, which helps absorb shocks and reduces movement within the box.

Examine the packaging's resistance to environmental factors such as moisture and temperature fluctuations. Water-resistant materials or coated boxes can be invaluable for shipping items that may encounter wet conditions. Furthermore, ensure that the box fits your product snugly; a well-fitted box reduces the chance of damage from shifting during transportation.

Tips: Conduct a drop test to evaluate your packaging's durability before committing to a large order. This simple test can reveal how well your chosen materials can withstand impacts and help you make informed decisions.

Consider Size and Weight Specifications for Boxes

When selecting the best shipping packaging boxes for your business needs, understanding size and weight specifications is crucial. According to a report by the Packaging Industry Association, approximately 30% of shipping costs are related to packaging waste, which can be minimized by choosing the right box sizes. Using boxes that are too large increases the chance of voids, leading to unnecessary shipping expenses. Conversely, boxes that are too small may result in damage to the contents, ultimately costing more than properly sized packages.

In addition to size, weight specifications also play a vital role in shipping efficiency. The Environmental Protection Agency indicated that lightweight packaging can reduce transportation emissions by up to 15%. Therefore, businesses should aim for materials that are both sturdy and lighter in weight, which can help decrease shipping costs while adhering to sustainability practices. Properly assessing the weight and dimensions of your products will not only facilitate smoother logistics but also enhance customer satisfaction, as customers appreciate receiving well-packaged goods that arrive undamaged.

Shipping Packaging Box Size and Weight Distribution

Evaluate Cost-Effectiveness and Environmental Impact of Choices

When selecting shipping packaging boxes, a critical consideration is the cost-effectiveness of the options available. Businesses need to evaluate the pricing structures of different materials and designs, weighing the initial investment against potential long-term savings. For example, while some packaging options may be less expensive upfront, they may not provide adequate protection for products, leading to increased returns and customer dissatisfaction. Therefore, it is essential to analyze total costs, which should include not only the purchase price but also the expenses related to shipping, handling, and potential losses due to damaged goods.

In addition to cost, the environmental impact of packaging materials is increasingly important for businesses aiming to enhance their sustainability practices. Choosing eco-friendly materials can not only reduce the carbon footprint but also resonate with environmentally conscious consumers. By opting for recyclable or biodegradable packaging options, companies can contribute to reducing waste in landfills and aligning their brand with global sustainability efforts.

Analyzing the lifecycle of packaging materials, including production and disposal methods, enables businesses to make informed choices that benefit both their financial bottom line and the environment.

Related Posts

-

Top Innovative Packaging Boxes Trends You Need to Know in 2024

-

What is the Importance of Custom Design Shipping Boxes for Your Business

-

Transform Your Brand with Unique Design Packaging Boxes That Stand Out

-

Top Packaging Boxes Manufacturers to Consider in 2025

-

Why Creative Boxes Are Revolutionizing Packaging in the E Commerce Industry

-

How to Choose the Right Packaging Supplies Boxes for Your Business Needs Based on Industry Trends