What is the Best Design for Shipping Boxes?

In the world of e-commerce, the design shipping boxes plays a critical role in protecting products. It's important to consider various factors that affect box performance. A well-designed box can reduce damage during transit and enhance the unboxing experience.

Choosing the right materials is crucial. Cardboard thickness, for instance, influences durability. Creative designs can attract customers, but practicality should not be overlooked. Boxes that don’t fit products properly can lead to issues. This creates a dilemma for many companies: how to balance aesthetics with functionality.

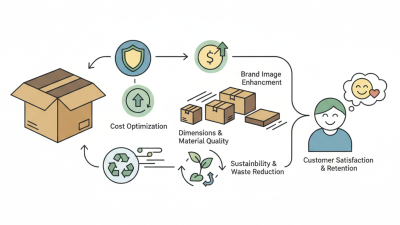

Furthermore, sustainability has become a pressing concern. Customers now prefer eco-friendly packaging. However, finding materials that are both sustainable and strong remains a challenge. Companies must reflect on their choices and strive for improvement. A thoughtful approach to design shipping boxes can set a brand apart in a crowded market.

Key Factors in Designing Shipping Boxes

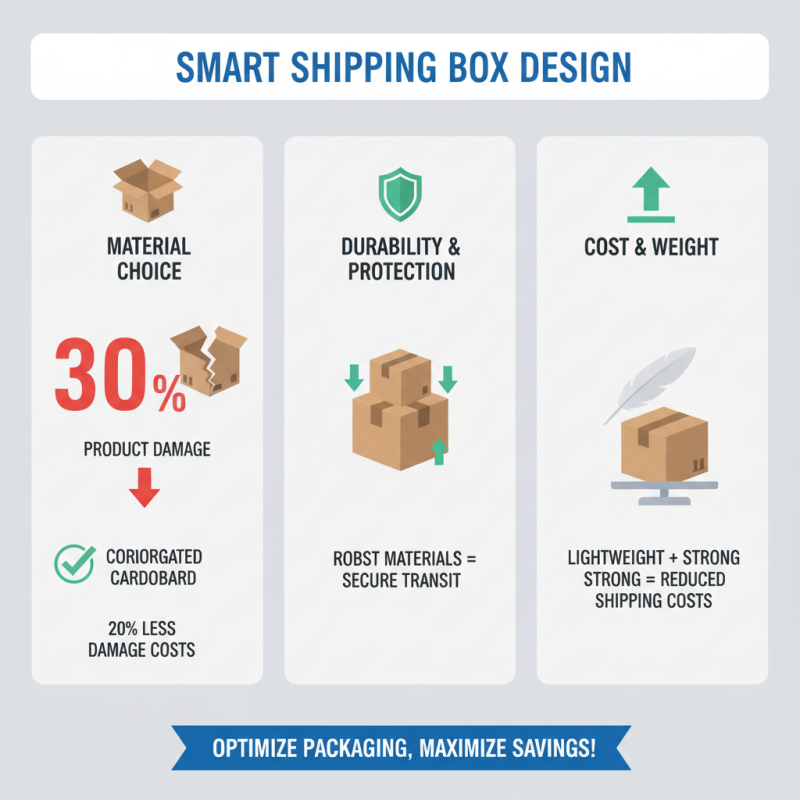

Designing effective shipping boxes requires attention to several key factors. Material choice is crucial. According to studies, around 30% of product damage occurs during transit, often due to inadequate packaging. Using robust materials can mitigate this risk. For example, corrugated cardboard has proven to reduce damage costs by up to 20%. Lightweight materials can also decrease shipping costs, but they must remain strong enough to protect the contents.

Box dimensions should align closely with the product size. A box that is too large can lead to increased movement and potential damage. Research indicates that proper sizing can reduce shipping costs by 15%. It’s also important to consider the environmental impact. Over 70% of consumers prefer sustainable packaging options. This demand pushes businesses to rethink their designs. Incorporating recyclable materials is not just a trend. It meets consumer expectations while potentially lowering material costs.

Additionally, branding plays a subtle yet significant role. Unique designs can capture consumer attention, influencing their perception and loyalty. Yet, focusing solely on aesthetics can sometimes overlook functionality. A balance is essential. Some companies find that flashy designs may not always protect products effectively. This highlights the importance of evaluating both form and function in shipping box design.

Materials Used for Durable Shipping Box Construction

When considering durable shipping box materials, cardboard is a commonly chosen option. It's lightweight and provides a shield against light impacts. Many companies use double-walled cardboard for extra strength. This material is often enough to protect delicate items during transit. However, it may not withstand moisture. Improper sealing can lead to damage.

Another excellent option is plastic containers. They are sturdy and resistant to water. These boxes can handle rough handling better than cardboard. But, they may be more expensive. Keep in mind that plastic is less eco-friendly. It’s essential to weigh the environmental impact of your choice.

Tips: Always test your materials. Conduct drop tests to assess durability. Remember to evaluate your shipping process. Understand the types of handling boxes will undergo. Your choice should reflect both protection needs and cost. Look for ways to improve your packaging regularly.

What is the Best Design for Shipping Boxes? - Materials Used for Durable Shipping Box Construction

| Material Type | Durability Rating | Weight Capacity | Cost per Unit |

|---|---|---|---|

| Corrugated Cardboard | High | 30 lbs | $0.50 |

| Plastic | Very High | 50 lbs | $1.50 |

| Wooden Crates | Very High | 100 lbs | $5.00 |

| Metal | Very High | 200 lbs | $10.00 |

| Pulp (Eco-friendly) | Medium | 25 lbs | $0.80 |

The Impact of Box Shape on Shipping Efficiency

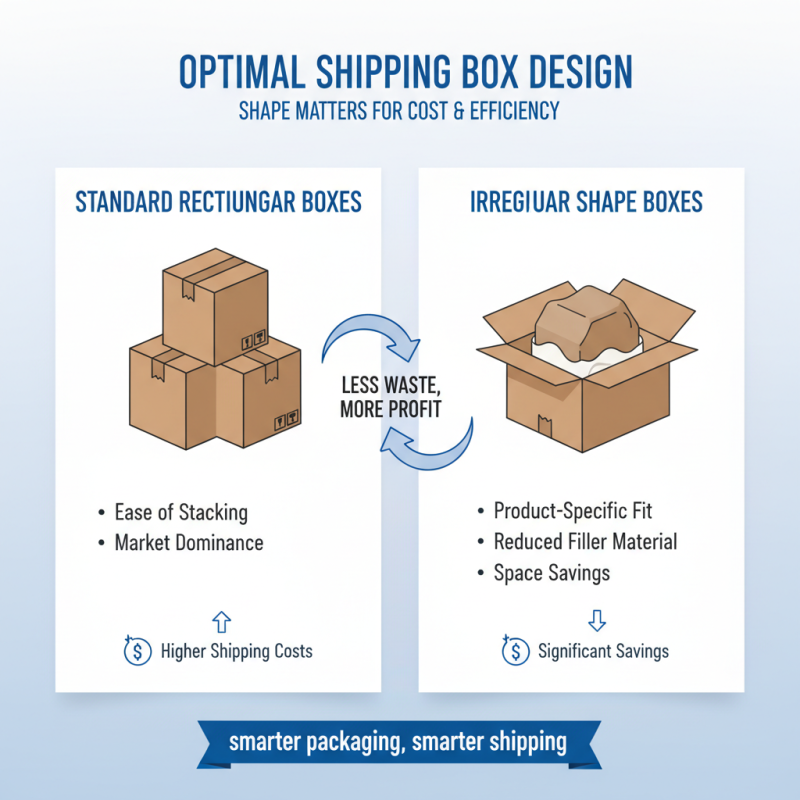

When considering the design of shipping boxes, box shape plays a crucial role. A well-designed box can reduce shipping costs and increase efficiency. Standard rectangular boxes often dominate the market due to their ease of stacking. However, irregular shapes sometimes fit products better, reducing the need for excess filler. This can lead to significant savings in materials and space.

The challenge lies in striking the right balance. Some companies experiment with different shapes, aiming for optimal performance. Yet, this can create complications. Oddly shaped boxes can be harder to stack efficiently, leading to wasted space in transport. It's a delicate dance between innovation and practicality. Also, the effects of box shape on consumer perception are worth considering. Creative designs can enhance brand appeal but may complicate logistics.

Ultimately, the design choice impacts the entire shipping process. A box's shape influences handling and storage. Unconventional designs might attract attention, yet they can inflate costs. Finding an ideal shape requires careful thought. Testing various designs can reveal surprising results. It’s essential to learn from both successes and failures in this journey.

Sustainability Considerations in Shipping Box Design

Shipping box design is crucial for sustainability. The packaging industry generates significant waste. According to a 2022 report by the World Economic Forum, up to 80% of plastic packaging ends up in landfills. This statistic highlights the need for eco-friendly alternatives.

One effective strategy is to use recyclable materials. Over 70% of consumers prefer environmentally friendly packaging. Choosing recyclable or biodegradable options can enhance brand perception. However, not all materials are created equal. Some may still cause environmental harm. It's essential to assess the entire lifecycle of packaging materials.

Tips: Consider using lighter materials to reduce shipping costs and emissions. Also, explore innovative designs to minimize waste. Streamlining box sizes can lead to better space utilization during transit. These small changes can lead to significant improvements over time. Ultimately, the aim should be to balance cost, functionality, and sustainability in box design.

Cost-Effectiveness Versus Quality in Shipping Box Choices

When choosing shipping boxes, cost-effectiveness and quality often compete. Many businesses prioritize low-cost options. However, this can lead to poor protection for items. A damaged product can result in higher costs due to returns and losses. It's a slippery slope between saving money and ensuring safe delivery.

Quality materials can increase the upfront cost. They provide better padding and protection. A sturdy box reduces the chance of breakage. Yet, some may overlook this to save a little cash upfront. It's essential to reflect on long-term costs. A damaged shipment affects customer satisfaction and reputation. Choosing wisely can safeguard your bottom line.

In many cases, finding a balance is crucial. Consider the value of the items being shipped. Higher-value products often warrant better packaging. Many companies fail to assess this properly. Their focus on saving can backfire. Investing in quality shipping boxes might save you money in the long run.

Cost-Effectiveness Versus Quality in Shipping Box Choices

Related Posts

-

What is the Importance of Custom Design Shipping Boxes for Your Business

-

How to Choose the Best Shipping Packaging Boxes for Your Business Needs

-

How to Choose the Right Packaging Supplies Boxes for Your Business Needs Based on Industry Trends

-

Top Innovative Packaging Boxes Trends You Need to Know in 2024

-

2026 Best Creative Packaging Boxes Ideas for Your Business Success?

-

Top 10 Inspiring Product Boxes for Unique Packaging Ideas?